HARIBO Fruit gummies: colourful variety

Our HARIBO fruit gummies have brought joy to everyday life for 100 years. With such diversity in shapes and flavours, there’s something for everyone.

Production – with attention to detail

Each and every HARIBO fruit gummy figure begins with a creative idea and is first sketched by hand. This template is then used to create a 3D sample drawing for a high-tech milling machine, which produces a plaster prototype. Once the new shape is perfect, several hundred stamps are created for production.

The figures – cast in the same mould

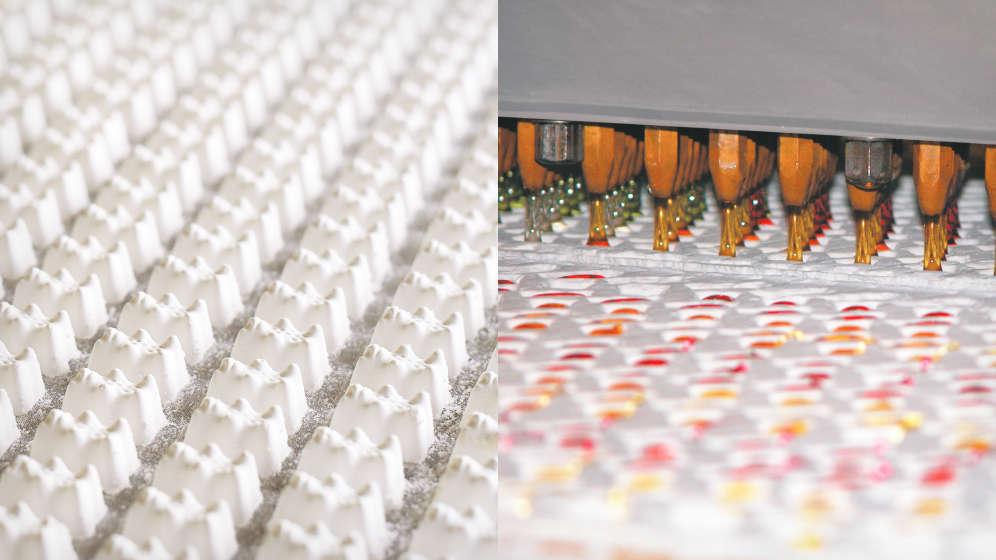

The figures are cast from a hot fruit gummy mass that has already been coloured with fruit and plant extracts. Mould casting requires shallow powder boxes, which are filled with smoothly levelled corn starch, the powder. During production, the figure stamps are inserted into the powder boxes from above, leaving behind an impression. A conveyor belt then transports the boxes to the next station, where nozzles fill the negative moulds with liquid fruit gummy in mere fractions of a second. The new fruit gummies then have plenty of time to solidify in drying rooms. Finally, a wax film is applied, giving them a sheen and preventing them from sticking together.

Special shapes – created with high pressure

The production process for extruder products is somewhat different: the high-pressure nozzles press the fruit gummy mass into the desired shape, thus creating, for example, a fruit gummy wheel. Whether pressed or cast, HARIBO’s fruit gummy variety brings joy to everyday life.